Introduction to Concrete Piers

Concrete bridge piers are crucial foundational structures in modern bridge construction. Here is a detailed introduction:

Definition and Function

Concrete bridge piers are support structures for bridges, located between two abutments. Their primary function is to support the bridge span structure and transfer dead loads and live loads from vehicles to the foundation. Bridge piers not only bear all the loads transmitted by the bridge span structure but also directly withstand soil pressure, water flow impact, ice pressure, ship collision force, and other loads.

Composition and Structure

Concrete bridge piers mainly consist of a coping, pier body, and foundation:

- Coping: Located at the top of the pier, it distributes the large and concentrated forces transmitted by the bridge span bearings evenly to the pier body. The coping should be constructed using high-strength materials, generally reinforced concrete with a grade not lower than 200, and have a thickness of not less than 40 centimeters. Additionally, the coping must have a large planar size to provide a necessary working surface for beam erection and maintenance.

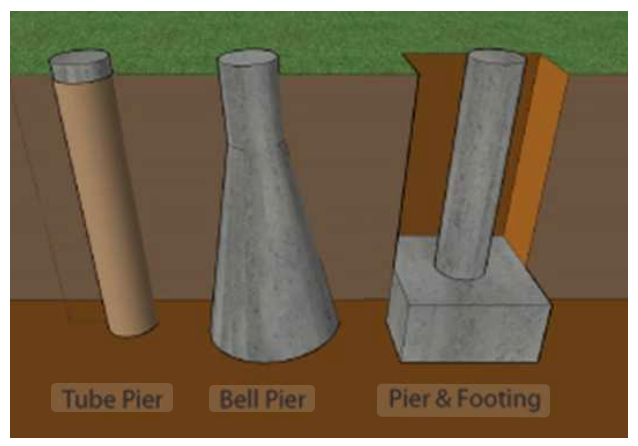

- Pier Body: The main structure supporting the bridge span, with sufficient strength, stiffness, and stability. The pier body is often poured with concrete or reinforced concrete and can have shapes such as rectangles, circles, tapers, etc.

- Foundation: Located at the bottom of the pier body and in direct contact with the ground, it transfers the load of the pier to the foundation. The foundation can be in the form of an expanded foundation, pile foundation, etc.

Material Characteristics

The main materials of concrete bridge piers are cement, sand, and crushed stone:

- Cement: The basic component of concrete, which enables other components to harden and become firm.

- Sand: Primarily serves as a filler, increasing the thickness and consistency of the concrete.

- Crushed Stone: Enhances the strength of the concrete, making it more durable.

Types and Application Conditions

Concrete bridge piers come in various types, such as gravity piers, lightweight piers (including thin-walled piers, framed piers, etc.), and pile-column piers:

- Gravity Pier: Balances external forces mainly through its own weight. It has advantages such as robustness, durability, simple construction, and easy access to materials. However, it requires a large amount of masonry, has a bulky and cumbersome appearance, reduces the effective aperture under the bridge, and increases the foundation load. It is suitable for large and medium-sized bridges with heavy loads and rivers with floating ice and driftwood.

- Lightweight Pier: Has a sleek and aesthetic appearance, requires less masonry, and reduces foundation load. It is suitable for bridges with lower foundation requirements and higher pier heights.

- Pile-Column Pier: Composed of a pile foundation and a columnar pier body. It has advantages such as easy construction and material savings. It is suitable for bridges of various spans, especially in plain areas.

Construction and Maintenance

The construction of concrete bridge piers includes foundation construction, pier body pouring, coping installation, and other steps. During the construction process, it is necessary to strictly control material quality, construction technology, and acceptance standards to ensure the quality and safety of the piers. In terms of maintenance, it is necessary to regularly inspect the piers for cracks, peeling, corrosion, and other issues and promptly repair and reinforce them.

Home

Home

Back

Back