Concrete Topping Calculator

Concrete topping: Key Considerations for High-Quality Completion

Concrete pouring is a crucial step in construction engineering, as its quality directly affects the stability and durability of the building structure. To ensure smooth and high-quality concrete pouring, the following are key considerations during the process:

I. Construction Preparation

- Warehouse Surface Cleaning and Inspection: Before concrete pouring, the warehouse surface must be cleaned to ensure no debris, water accumulation, etc., to guarantee the cleanliness of the pouring surface. Additionally, the pouring surface must pass inspection before concrete pouring can commence.

- Inspection of Forms and Steel Bars: Check that forms, steel bars, etc., are securely installed, positioned correctly, and that vibrating equipment is in good condition to ensure smooth subsequent pouring work.

II. Material Selection and Quality Control

- Concrete Materials: Select concrete materials that meet design requirements, including cement, sand, gravel, etc., and mix them strictly according to the specified proportions. At the same time, conduct rigorous quality inspections on raw materials to ensure they meet relevant standards.

- Slump Control: During mixing, control the concrete's slump to ensure it has good workability and pouring quality.

III. topping Operations and Techniques

- topping Methods: Use the spreading method or stepped method for construction, avoiding the rolling method, to ensure uniform and dense pouring. Pour in layers with a certain thickness, order, direction, and ensure the pouring layer is flat. When pouring walls, they should rise symmetrically and uniformly, with a pouring thickness generally between 30cm and 50cm.

- Vibration Requirements: Vibration is crucial for ensuring concrete compactness. Vibrating points should be arranged in a plum blossom pattern and moved in a row-column order to ensure no missed or over-vibration. During vibration, observe the concrete's vibration and adjust the vibration force and frequency in a timely manner. Additionally, conduct compactness tests on poured concrete to ensure it meets design requirements.

- topping Speed and Time Control: Concrete pouring should be continuous, with the time interval between two pours not exceeding the concrete's initial setting time to prevent cold joints. At the same time, pouring speed should be arranged reasonably based on the concrete's setting time and pouring volume.

- Setting Observation Points: During pouring, set displacement deformation observation points to regularly observe formwork shifts and check reinforcement to ensure pouring accuracy and stability.

IV. Temperature and Humidity Control

- High-Temperature Environments: In high-temperature environments, use methods such as spraying and covering to reduce the concrete surface temperature.

- Low-Temperature Environments: In low-temperature environments, take measures such as heating and insulation to increase concrete temperature and ensure normal setting.

V. Crack Prevention Measures

- Material Selection: Use low-heat cement to reduce internal stress in the concrete.

- topping and Vibration Control: Control the concrete pouring speed and vibration force to avoid excessive stress concentration.

- Curing: After pouring, promptly cover and cure the concrete to keep the surface moist and reduce dry shrinkage cracks caused by water evaporation.

VI. Safety Operations and Lighting

- Safety Protection: Construction personnel should wear safety helmets, protective clothing, and other personal protective equipment to ensure the safe use of vibrating equipment and prevent accidents such as electric shock and mechanical injury. Additionally, set up safety warning signs to remind construction personnel of safety.

- Lighting Equipment: Ensure sufficient lighting equipment during nighttime pouring to ensure construction safety and pouring quality.

VII. Curing and Protection

- Surface Troweling and Texturing: After concrete pouring, perform surface troweling to ensure a smooth and flat concrete surface; also, perform texturing to increase the surface roughness and improve adhesion with subsequent decorative layers.

- Covering and Curing: Perform covering and curing to keep the concrete surface moist and prevent dry shrinkage cracks caused by water evaporation. During the curing process, regularly check the concrete's quality to promptly identify and address potential issues.

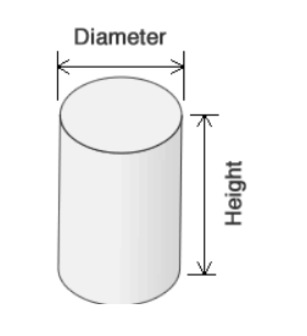

How to Calculate Concrete Yardage

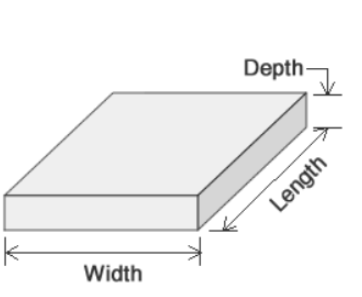

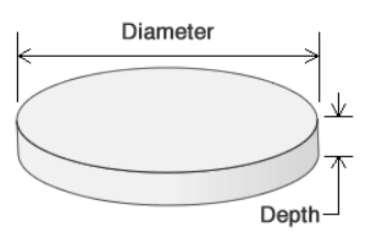

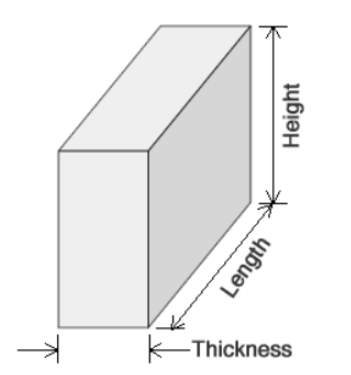

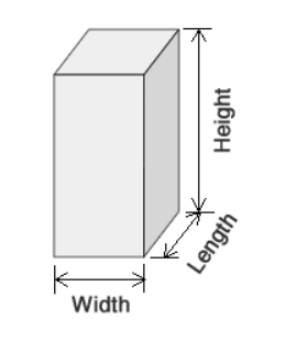

Using measurements in feet:

Using measurements in feet:

Using measurements in feet:

Using measurements in feet:

Using measurements in feet:

Using measurements in feet:

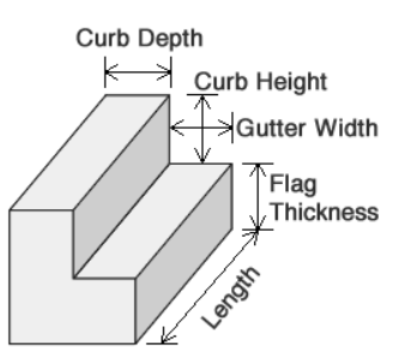

We calculate the volume in sections from the ground to the top of each section. The Curb and Gutter are each a section.

Concrete Calculator© - All Rights Reserved 2024

Home

Home

Back

Back